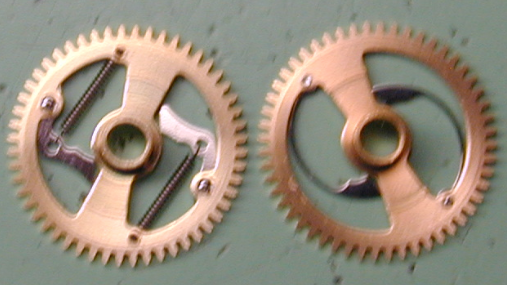

(photo of UTC wheels for hour hand assembly)

In my long association with IWC I continue to be surprised every now and then by the technical modifications and improvements quietly introduced at their Schaffhausen factory to existing calibre movements and timepieces.

Unlike many other watch companies who make a big to do with minor introductions of features which add little or no real value to the consumer or watch owner IWC has always put their watchmakers hard at work in continuing quests for improvements to parts that offer better, smoother, and more reliable operations.

Moreover, IWC’s service communications department, since 2007, has provided their official after-sales service platforms with clear pictorial documents illustrating the modifications and upgrades to both movement and case parts. This is in conjunction with the manufacturing changes noted above.

I would like to point to what appears to be a recent change on the UTC pilot timepieces from the previous calibre C37526 to the newer C30710 whose base is powered by an ETA 2892. To start with the main plate has always been modified to accommodate IWC’s in-house UTC calendar mechanism (it’s not a simple add-on module).

The above photo showing two wheels are called the “stundenzeigerrad komplett” in German or in English “wheel for hour hand assembly”. Its function is to carry the hour hand and allow rapid changeover of that hand in different time zones without disturbing the minute hand and/or continuation of appropriate running time.

The old-version wheel shown on the left is comprised of seven intricate parts with the miniature, ball-point-pen like, springs allowing the clicks to jump from tooth to tooth as one adjusts the hour hand to any other time zone. These springs are preset and difficult to assemble at the factory while at the same time getting the correct tension. Also, they may also loosen a bit over the years depending on the use of these functions though I have not experienced or received any reports about such.

The new-version wheel on the right is comprised of only five parts vs. seven with the round clicks more easily adjustable by a skilled watchmaker when necessary to assure proper tension.

While these hidden, behind the hood, modifications aren’t exactly considered sexy since the average person has no clue anyway how the UTC operates I, nevertheless, consider such subtle changes ever so important for a company steeped in engineering and which prior to 1970 manufactured almost every mechanical movement (over 50 calibres) in-house.

So I see it fit to take the opportunity to bring our readers an awareness of how IWC is busy behind the scenes looking always to make a better mouse trap. And, all this, without public fanfare and a lot of noise.

Kudos to IWC and its deep thinking watchmakers hard at work.

Regards,

Jack Freedman